In the world of technical textiles, few materials offer the same combination of strength, flexibility, and adaptability as double wall fabric. For industries that rely on high-performance inflatable structures—ranging from water sports and aerospace to emergency shelters and medical devices—the choice of base fabric can directly impact product reliability and user safety. Many Double Wall Fabric Manufacturers are now promoting this material as a superior solution, especially when compared with traditional options like nylon, canvas, and standard PVC-coated fabrics.

Structural Advantages of Double Wall Fabric

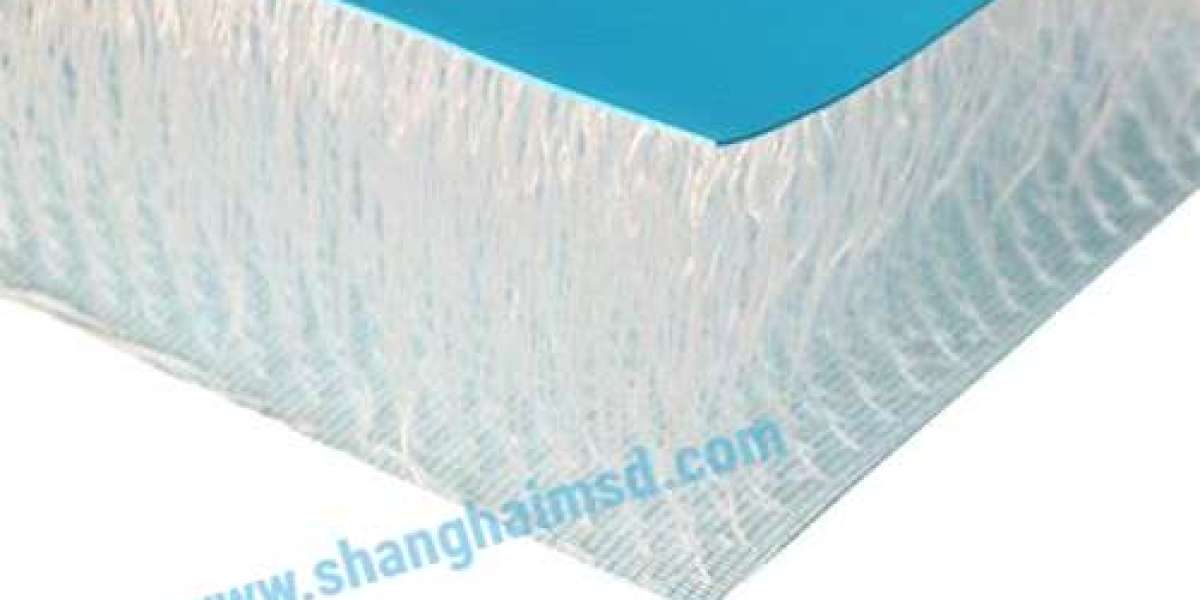

Double wall fabric is uniquely engineered with two layers of woven textile connected by thousands of vertical fibers. When inflated, this internal support system helps the fabric maintain a flat, rigid shape, making it ideal for load-bearing or structural inflatable applications. In contrast, materials like nylon or single-layer PVC may sag or warp under pressure, making them less suitable for platforms or high-stress applications.

This innovative construction allows products made with double wall fabric to achieve high pressure ratings without compromising on weight. The result is a material that is both lightweight and strong, which is a critical advantage for portable or deployable solutions.

Performance in Harsh Environments

When comparing double wall fabric to alternatives, one of the most significant advantages lies in its ability to endure harsh environments. Double Wall Fabric Manufacturers often enhance their textiles with UV-resistant coatings, mildew inhibitors, and anti-abrasion layers. This makes the fabric not only long-lasting but also highly functional in conditions involving sunlight, saltwater, or frequent mechanical stress.

For instance, canvas—though durable—is prone to moisture absorption and mildew, which limits its lifespan in marine or humid settings. Nylon, while lightweight and cost-effective, can degrade quickly under UV exposure unless heavily treated. Double wall fabric, by comparison, maintains dimensional stability and integrity even with prolonged outdoor use.

Functionality and Versatility

Another benefit that sets double wall fabric apart is its versatility. Thanks to its stable, inflated shape and smooth surface, it can be used for a variety of applications: inflatable paddle boards, tents, operating tables, military bridges, and more. Manufacturers offer customization options such as TPU or PVC coatings, various thickness levels, and tailored pressure tolerances to meet different industry requirements.

This level of adaptability is difficult to match with traditional materials. For example, a single-layer PVC fabric may be ideal for flexible inflatables like tubes or rafts, but it cannot offer the rigid form factor required for stable platforms. Similarly, woven fabrics without internal reinforcement often struggle to combine flexibility with load-bearing capacity.

Long-Term Investment in Quality

While double wall fabric may come with a higher upfront cost compared to simpler materials, its long-term benefits in performance, maintenance, and safety make it a smart investment. For buyers seeking consistent quality, it's essential to work with experienced Double Wall Fabric Manufacturers who understand industry-specific needs and offer proven material specifications.

By choosing the right fabric, businesses not only extend the life cycle of their products but also enhance end-user satisfaction—an important competitive advantage in today’s quality-driven markets. For more technical insights and material solutions, visit shanghaimsd.com .